POPULAR PRODUCTS

ABOUT US

Dalian Dongxing Forging Co., Ltd.

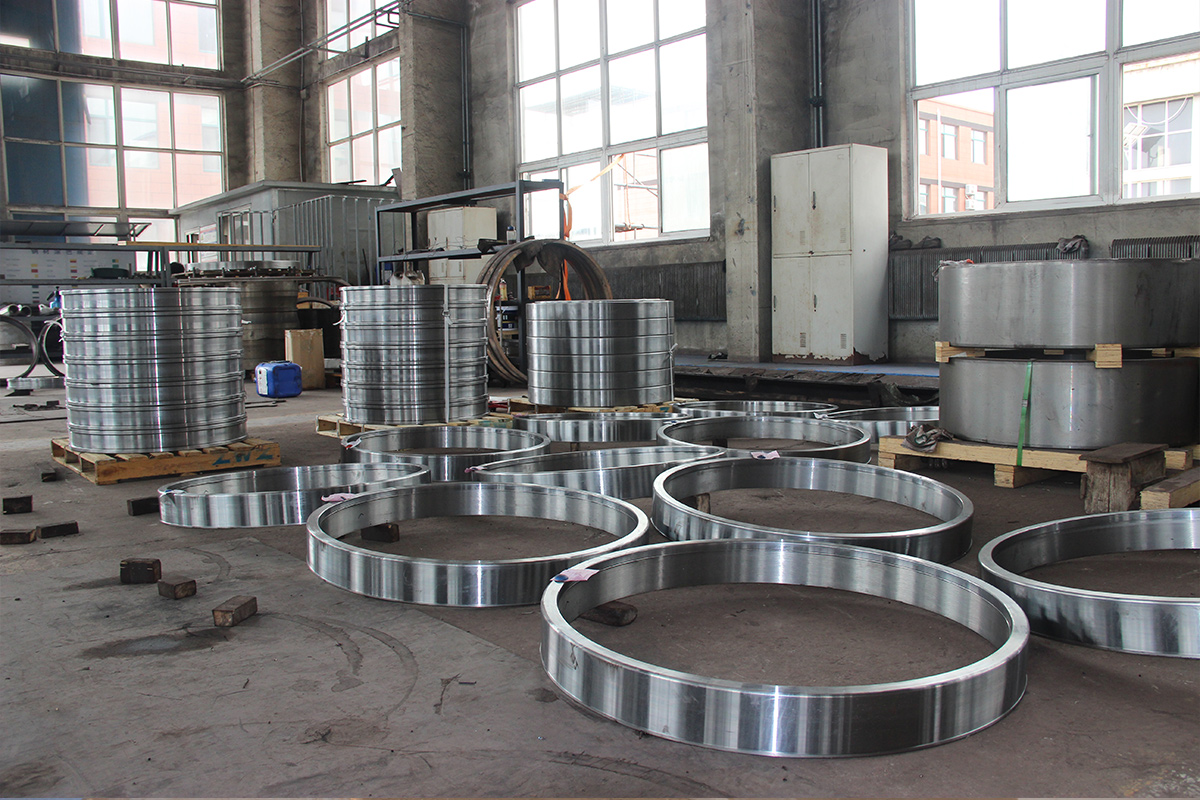

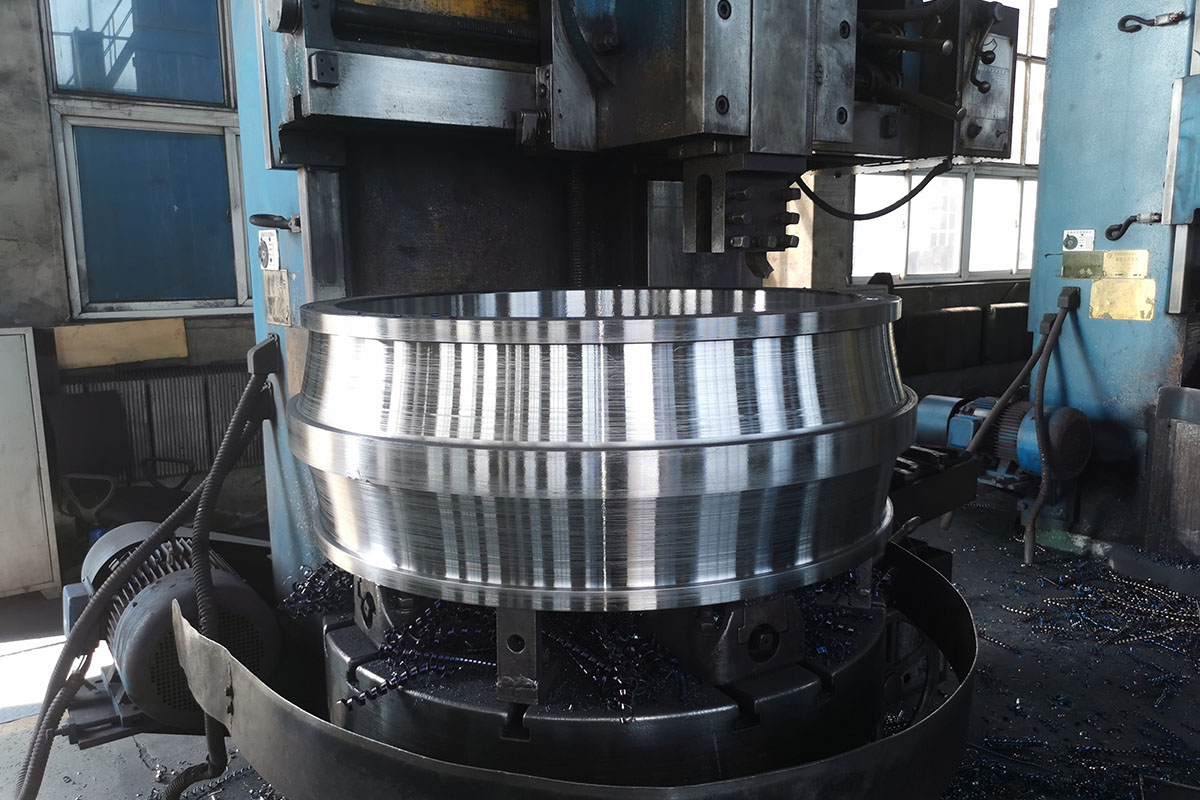

Dalian Dongxing Forging, located in Jinpu New Area, Dalian, Liaoning Province, China, is close to Shenyang-Haikou Expressway and National Highway 202 (G202), with very convenient transportation conditions. We are an important supplier of ring forgings in Northeast China and mainly provide high-quality bearing forgings, pipe flanges, forged rings, forged shafts, modules and other small and medium-sized forgings for customers in metallurgy, petrochemical, mining and machinery industries. Founded in 1985, and transformed in 1999, we completed the construction of our new factory and put it into operation in 2013, which obtained German Rhine ISO 9001:2015 certification in 2014. With a total investment of 97 million yuan, our new factory covers an area of 15,000 square meters and a gross floor area of 9,000 square meters, with an annual output of about 10 thousand tons of forgings and annual sales of nearly 100 million CNY. We have more than sixty employees and dozens of technicians and inspectors.

OUR COMPANY

Dalian Dongxing Forging Co., Ltd.

Dalian Dongxing Forging, located in Jinpu New Area, Dalian, Liaoning Province, China, is close to Shenyang-Haikou Expressway and National Highway 202 (G202), with very convenient transportation conditions. We are an important supplier of ring forgings in Northeast China and mainly provide high-quality bearing forgings, pipe flanges, forged rings, forged shafts, modules and other small and medium-sized forgings for customers in metallurgy, petrochemical, mining and machinery industries. Founded in 1985, and transformed in 1999, we completed the construction of our new factory and put it into operation in 2013, which obtained German Rhine ISO 9001:2015 certification in 2014. With a total investment of 97 million yuan, our new factory covers an area of 15,000 square meters and a gross floor area of 9,000 square meters, with an annual output of about 10 thousand tons of forgings and annual sales of nearly 100 million CNY. We have more than sixty employees and dozens of technicians and inspectors.

ENVIRONMENTAL EQUIPMENT

After-Sale Service

Provide you with more cost-effective products and technical services

Adhering to the principle of "quality first, customer first", we provide customers with products of reliable quality and superior services in a timely manner and at reasonable prices. We have won high reputation and unanimous praise from customers.

NEWS INFORMATION

09

2021 -11

09

2021 -11

09

2021 -11

09

2021 -11

09

2021 -11

Dalian Dongxing Forging Co., Ltd.

The main products are bearing ring forgings for metallurgy, mining and various machinery industries, and all kinds of small and medium-sized forgings.

Add: Dalian Jinpu New Area

Tel: +86-411-87350155

If you have any questions, please contact us

Our Strength

Copyright: Dalian Dongxing Forging Co., Ltd. 辽ICP备********号-1 Powered by www.300.cn

0411-87350155

0411-87350155

dongxingduanzao@vip.126.com

dongxingduanzao@vip.126.com